How to Run the Bowie & Dick Test Properly

- 09, Sep 2021 16:07

- Heru

As we already know, the bowie & dick test is one of the sterilization tests that uses a chemical indicator sheet. Developed to monitor the effectiveness of air removal in pre-vacuum steam sterilizers (mechanical air removal) and providing the validation criteria for the condition of the tool, and also helps to detect what the good steam parameters are. So the quality of the steam will not interfere with the sterilization process.

How to use the bowie & dick test pack is explained in the Association for the Advancement of Medical Instrumentation's (AAMI) guideline, ANSI / AAMI ST79. This guideline is made for anyone who wants to do a bowie & dick test, and they need to pay attention to the terms and conditions that have been set AAMI guideline, so the testing process can be carried out effectively.

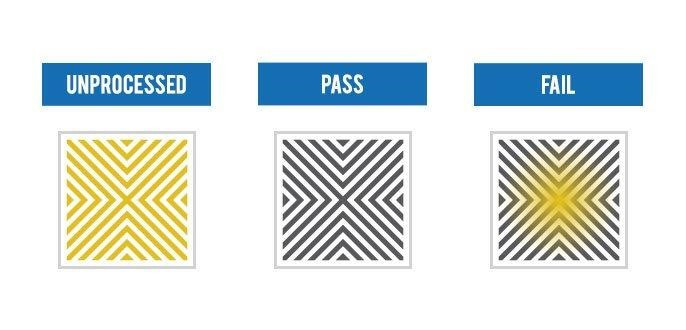

When we are doing the Bowie & Dick test, it takes 3 consecutive stages of testing to finally pass the validation test. The results of the Bowie & Dick test process are seen using an indicator in the form of a chemical heat-sensitive sheet consisting of several layers of paper and foam. This sheet will change color when exposed to a certain pressure level of saturated steam. The result is said to be successful if the sheet changes color evenly, without any other color stains. And vice versa, if the changed color is not spread evenly, aka there is still another color stains, then the result is considered a failure.

Here are 5 steps of how to run / operate the bowie & dick test properly:

- Firstly, perform a heating cycle process on the sterilizer. This heating cycle process is carried out to avoid errors and failures in the results of the bowie & dick test carried out.

- Secondly, after the heating cycle is complete, place the test pack in the middle of the bottom shelf of the sterilization chamber, or in a sterilizer basket. Make sure to always put the test pack right above the disposal line, and also make sure that there are no other instruments / tools in the autoclave. This disposal line is important to qualify the air in the autoclave, so the remaining air will enter the test pack later.

- Thirdly, perform a sterilization cycle test on the test pack for 3.5 to 4 minutes by using and paying attention to the specified parameter cycles, generally around 1340 Celsius, even though AAMI does not actually provide a specific explanation about this parameter cycle.

- Fourthly, check the sheet from the test pack whether the color has changed evenly or not. This sheet is a chemical indicator that has a special ink, so it can produce different colors than before.

- Lastly, take and see the results of the sheet from the test pack and interpret the results. The results of this test will not only interpret air-leaks, but also information about the presence of humidity levels, steam quality problems, and the presence of NCG (Non-condensable gas) cycles.

Regarding the failure that occurred in the Bowie & Dick test, it could be due to the following things that occurred in the sterilization system, such as:

- Air leak during the exhaust process (usually occurs in the initial vacuum phase).

- There is a steam supply problem, such as a poor / bad quality steam supply when expelled from the sterilizer.

- Failure of the steam trap or safety valve to create a good vacuum.

If a failure occurs, the advantage of this bowie & dick test is that the test can be repeated, but if it continues to give failed results, the autoclave machine must be stopped immediately aka the test is stopped.

Check our bowie & dick test pack product on the Hartech Indonesia website, hartechindonesia.com. Don't hesitate to contact our sales team for additional information, we are always ready to serve you wholeheartedly with our best products from our trustworthy brand partners.

- 14, Sep 2022 13:43

- 29, Oct 2021 09:23

- 28, Oct 2021 09:53

- 27, Oct 2021 10:25

- 27, Oct 2021 10:20

- 26, Oct 2021 11:05

- 26, Oct 2021 11:00

- 25, Oct 2021 10:37

- 25, Oct 2021 10:32

- 22, Oct 2021 11:30

- 22, Oct 2021 11:27

- 22, Oct 2021 11:21

- 21, Oct 2021 11:58

- 21, Oct 2021 11:51

- 21, Oct 2021 11:44

- 21, Oct 2021 11:36

- 18, Oct 2021 13:02

- 15, Oct 2021 13:37

- 15, Oct 2021 13:33

- 15, Oct 2021 13:27

- 14, Oct 2021 10:58

- 14, Oct 2021 10:36

- 14, Oct 2021 10:31

- 14, Oct 2021 10:27

- 08, Oct 2021 12:11

- 08, Oct 2021 12:06

- 08, Oct 2021 12:01

- 07, Oct 2021 17:24

- 07, Oct 2021 09:57

- 06, Oct 2021 12:29

- 06, Oct 2021 12:22

- 05, Oct 2021 13:35

- 05, Oct 2021 13:30

- 01, Oct 2021 12:01

- 01, Oct 2021 11:44

- 30, Sep 2021 12:55

- 29, Sep 2021 13:48

- 28, Sep 2021 11:43

- 28, Sep 2021 11:38

- 28, Sep 2021 11:35

- 27, Sep 2021 12:21

- 24, Sep 2021 10:40

- 24, Sep 2021 10:37

- 24, Sep 2021 10:32

- 24, Sep 2021 10:27

- 24, Sep 2021 10:23

- 23, Sep 2021 21:42

- 23, Sep 2021 21:34

- 23, Sep 2021 21:29

- 23, Sep 2021 21:25

- 22, Sep 2021 11:10

- 22, Sep 2021 11:06

- 22, Sep 2021 10:44

- 22, Sep 2021 10:38

- 22, Sep 2021 10:24

- 20, Sep 2021 12:09

- 20, Sep 2021 11:53

- 20, Sep 2021 11:45

- 17, Sep 2021 10:16

- 17, Sep 2021 10:10

- 17, Sep 2021 10:02

- 17, Sep 2021 09:51

- 17, Sep 2021 09:46

- 14, Sep 2021 12:45

- 14, Sep 2021 12:35

- 14, Sep 2021 12:29

- 14, Sep 2021 12:25

- 14, Sep 2021 12:09

- 13, Sep 2021 14:59

- 13, Sep 2021 14:54

- 13, Sep 2021 14:07

- 13, Sep 2021 14:01

- 09, Sep 2021 16:16

- 09, Sep 2021 15:57

- 09, Sep 2021 15:52

- 02, Sep 2021 09:24

- 02, Sep 2021 08:29

- 01, Sep 2021 08:49

- 01, Sep 2021 08:33

- 31, Aug 2021 08:46

- 31, Aug 2021 08:25

- 30, Aug 2021 09:40

- 30, Aug 2021 09:20

- 27, Aug 2021 08:52

- 27, Aug 2021 08:14

- 26, Aug 2021 12:08

- 26, Aug 2021 12:00

- 25, Aug 2021 08:32

- 25, Aug 2021 08:17

- 19, Aug 2021 08:37

- 19, Aug 2021 08:19

- 17, Aug 2021 08:40

- 17, Aug 2021 08:27

- 16, Aug 2021 08:31

- 12, Aug 2021 08:57

- 12, Aug 2021 08:41

- 11, Aug 2021 09:40

- 11, Aug 2021 08:50

- 10, Aug 2021 09:05

- 10, Aug 2021 08:47

- 09, Aug 2021 09:46

- 09, Aug 2021 09:08

- 05, Aug 2021 17:19

- 05, Aug 2021 16:08

- 18, Sep 2020 01:54

- 18, Sep 2020 01:50

- 18, Sep 2020 01:48

.jpg)

.jpg)

.jpg)